Rotary vane pumps are often the first choice for vacuum handling and gas sampling applications that require a high flow capability relative to the size of the pump.

Rotary vane technology features low pulsation and low vibration, which enable consistent flow rates with minimal vibration. These traits make these units ideal for Medical, Lab Life Science devices, life-saving equipment, and Industrial, Environmental, and Food & Beverage markets.

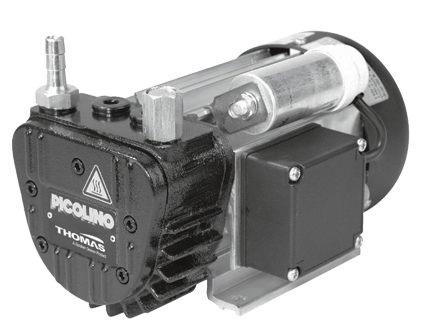

Rotary Vane Pumps by Thomas

Thomas rotary vane pumps and compressors provide a free flow ranging from 1.2 l/min (0.04 cfm) up to 198.0 l/min (7.0 cfm), with maximum continuous operating vacuum up to 930 mbar (27.5 in.Hg), and maximum continuous operating pressures up to 1 bar (14.5 psi).Our rotary vane portfolio can be driven by various drive options. Customers can choose from Ironless Core DC, Permanent Split Capacitor (PSC), Split Phase (SP), Permanent Magnet DC (PM), and Brushless DC (BLDC) options.

Benefits of Thomas Rotary Vane Pumps and Compressors

These oil-less and self-lubricating units provide the highest flow to size ratio and lowest pulsation of all five gas technologies offered by Thomas. Rotary vane technology can feature an orientation of vanes that enables for a reversible direction of flow in selected series. That makes them an ideal component for applications that require active inflation and deflation, such as in medical compression sleeves for deep vein thrombosis.

Perfect Fit for a Variety of OEM Devices

Original Equipment Manufacturers that need a compact-sized unit with outstanding performance as well as high flow with minimal backpressure, often reach for Thomas rotary vane products. This technology is the perfect fit for applications that require high flow to size ratio.These components have a proven record of successful utilization in a wide range of industries and applications. Thanks to the reversible flow direction, some components are a perfect fit for the application requiring inflation or deflation, or intake and outtake motion.

Featured Applications using Rotary Vane Pumps and Compressors

Customized For Your OEM Needs

Thomas’ Rotary Vane pumps and compressors can be customized to meet even the most complex requirements of the customer. On top of that, their design allows them to tailor the performance by adjusting the number of vanes, varying the component materials and motor selection to meet the performance range required in a given application. We offer a selection of plastic and carbon head/vane material that can be selected based on the operating environment or media being pumped.Plastic head and vane configured models are recommended for use in humid environments due to moisture tolerance. Carbon head and vane components provide improved performance compared to plastic parts. Carbon components reduce leakage, improve sound quality, and offer more precise tolerances.Apart from the different composite materials, our engineers can customize the number of vanes in the pump head and their orientation. That enables the pump-head to run also in reverse motion.

How Rotary Vane Pumps and Compressors Work?

The rotary vane unit cylindrical head consists of a rotor with slots for vanes (pump blades). The rotary vane pump uses centrifugal force to push the vanes against the cylindrical head/housing wall and slide against the cylinder's internal surface as the rotor turns.This movement creates a gap between the two vanes and the cylinder. As the rotor turns, the gap is being moved, and the volume of the gas is being compressed, increasing the pressure and creating a vacuum.Construction of these positive displacement pumps allows us to create units smaller than the coin that can still provide amazing performance for thousands of hours.