Operating Principle V-Series

Pressure increase by volume reduction is the principle behind rotary vane operation. In a cylindrical housing a rotor is positioned eccentrically so that it is on the top almost touching the cylinder. Rotor blades or vanes as they are called, are positioned inside rotor slots.

When the rotor starts turning, due to centrifugal force the blades are thrown out and slide against the internal surface of the cylinder. In this way a cell is formed between two blades with a volume that changes constantly during rotation. Air enters from the inlet port into a cell until the rear blade reaches the far end of the inlet port. At this point the cell has achieved its maximum air volume. As the cell then moves away from the port its volume becomes smaller and smaller, the air is thus compressed and the pressure rises. This continues until the pressure in the cell exceeds that in the pressure chamber and the compressed air then exits through the outlet port.

Some models are fitted with exhaust valves which stop the backflow of this discharged air if the maximum pressure has been reached. In a vacuum pump the process is similar, but the cell gives decreasing pressure, and the chamber is at atmospheric pressure. With pressure-vacuum pumps the lower end of the inlet port(s) for the vacuum is moved forward. The cell can now be filled through second inlet. To avoid impairing the vacuum, this second inlet port is located about one cell segment away from the main suction port. The ratio between vacuum and pressure capacities can be influenced by the choice of inlet port.

With available volume flows ranging from 40 to 1500 m³/h, the VCS models are tailored to boost the established performance parameters of this reliable technology. This series is characterized by low ownership costs and a design that emphasizes reduced weight, noise, and size, making the pumps highly adaptable for various industrial applications. The V-VCS series offers a seamless and efficient solution for those seeking robust vacuum performance.

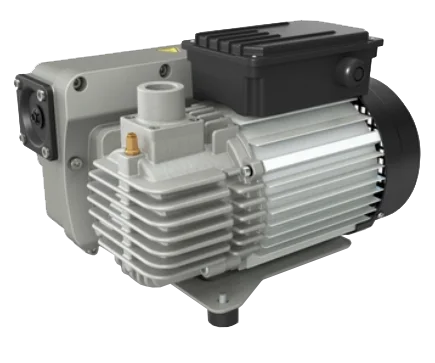

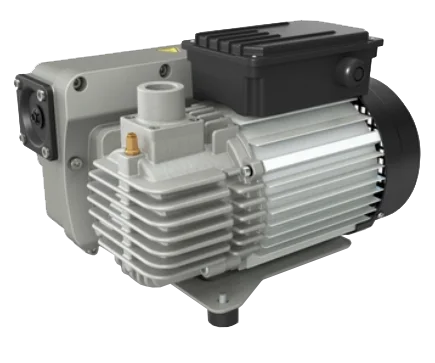

Capacities ranging from 5.9 to 10.6 cfm. The ultimate vacuum can be selected by operator at either 29.86inHg for fi ne vacuum or 29.63inHg for coarse vacuum. Needs little space thanks to overhung rotor design and integral motor. Fitted as standard with fine mesh filter, vacuum non-return valve and oil separator. Very quiet operation.

Datasheet

Capacities ranging from 5.9 to 10.6 cfm. The ultimate vacuum can be selected by operator at either 29.86inHg for fi ne vacuum or 29.63inHg for coarse vacuum. Needs little space thanks to overhung rotor design and integral motor. Fitted as standard with fine mesh filter, vacuum non-return valve and oil separator. Very quiet operation.

Datasheet

The V-VTA series of pumps are commonly used in applications such as packaging, printing, plastics, woodworking, and many others where a reliable source of vacuum is required.

Datasheet

A capacity range of 11.8 to 15.6 cubic feet per minute (cfm) and an ultimate vacuum of 29.86 inches of mercury (in.HgV). This vacuum pump is designed specifically for small vacuum packaging machines and features a flange motor, bearings on both sides of the rotor, and air cooling.

In addition, this model of Elmo Rietschle vacuum pump is fitted as standard with a fine mesh filter to prevent contamination, a vacuum non-return valve to maintain vacuum level, and an oil separator to prevent oil carry-over. These features help to ensure reliable and efficient operation of the vacuum pump in a range of industrial applications.

Oil-flooded rotary vane vacuum pumps with 1~ motors and 3~ IE2 motors Capacities ranging from 15 to 28CFM, ultimate vacuum 0.5 mbar (abs.).Flange motor, bearings on both sides of the rotor, air cooling. Fitted as standard with fine mesh filter, vacuum non-return valve, gas ballast valve and oil separator. Flange mounted motors correspond to DIN EN 60034 and have IP 55 protection and insulation class F.

Datasheet

Oil-flooded rotary vane vacuum pumps with IE3 motors. Capacities ranging from 15 to 28CFM, ultimate vacuum 10 mbar (abs.).Flange motor, bearings on both sides of the rotor, air cooling. Fitted as standard with fine mesh filter, vacuum non-return valve, gas ballast valve and oil separator. Flange mounted motors correspond to DIN EN 60034 and have IP 55 protection and insulation class F.

Datasheet

The staple in the oil lubricated rotary vane market is the Elmo Rietschle V-Series. Utilizing centrifugal force to create vacuum, this tried and true VC 50 and VC 75 have decades of Elmo Rietschle expertise incorporated into this robust design. This oil-flooded product can maintain vacuum levels as low as 29.91 inHg, having a maximum flow of 49.4 CFM. This product provides multiple features that benefit each industry it serves.